Electric Corded Cutt-Off Machine Suppliers

WUYI KRAIN TOOLS CO., LTD.

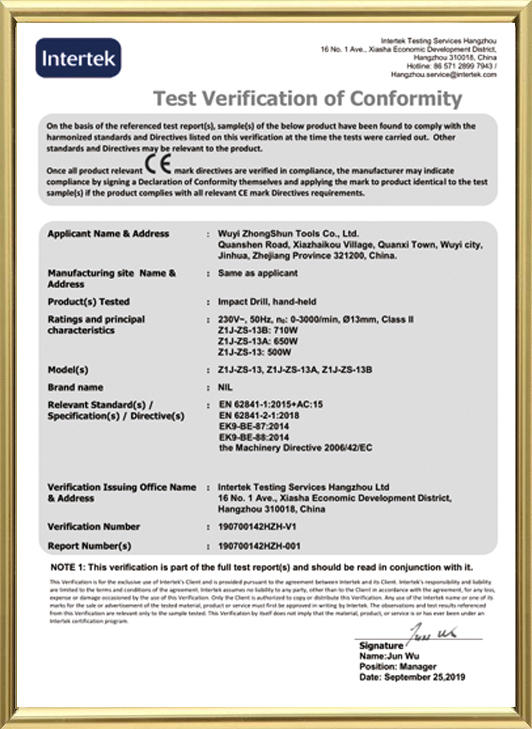

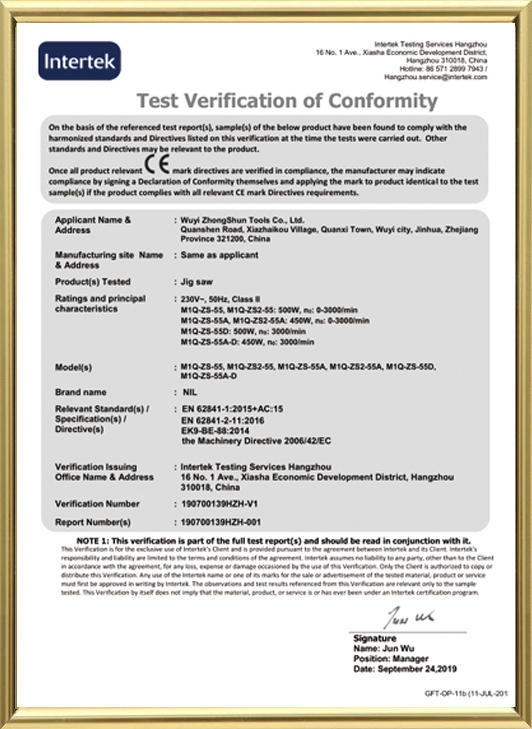

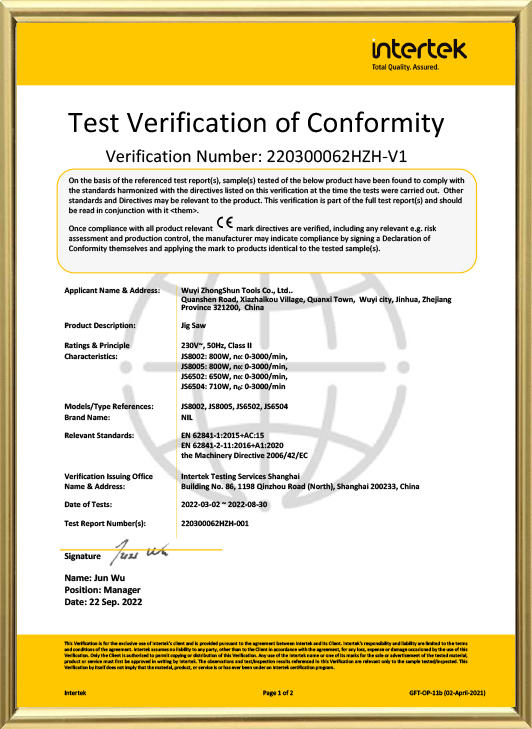

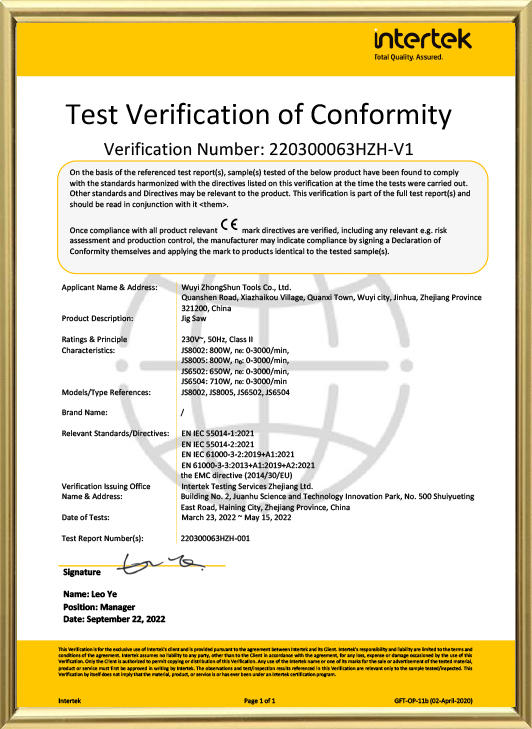

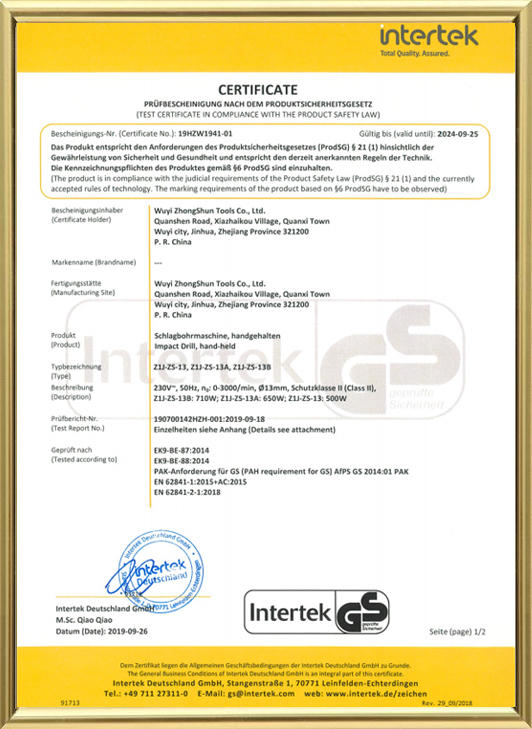

Wuyi KRAIN Tools Co., Ltd. was Founded in 2012 at Quanshen Road, Quanxi Town, Wuyi City, Zhejiang Province.(near Yiwu and Yongkang), Wuyi Krain Tools Co., Ltd is an export company of Wuyi Zhongshun Tools Co., Ltd. and Zhejiang Quantou Intelligent Technology Co., Ltd, We have 11 years of OEM/ODM experience as a high quality Electric Corded Cutt-off machine Manufacturer and Electric Corded Cutt-off machine Supplier. We always provide customers with Stable quality products at Reasonable prices. Our team has good after-sales service.

The factory covered an area of over 8000 square meters building areas with 4 floors.

1st floor make outer carton and label/manual. 2nd-floor rotor/stator production

3rd floor power tools production,4th floor garden tools production.More than 100 staffs work here. We also passed ISO9001, CE, GS, EMC, RoHS, etc.

Our main product is Jig Saw, Drills, Grinders, Cordless Drill, Car Polisher, Reciprocating saw, belt sander, Power Tools Set, Mixer, Chain Saw, Brush Cutter and so on.

NEWS CENTER

-

A Comparative Analysis Of China Lithium Cordless Drills And Their Global Counterparts

Wholesale High Quality China Lithium Cordless Drill Exporter The quality of power tools, including lithium cor...

View More -

The Good Convenience And Mobility Of Lithium Cordless Drills

Custom Sale High Quality Lithium Cordless Drill Manufacturing The advent of lithium cordless drills has marked...

View More -

The Rise Of China Lithium Cordless Drills A New Era In Power Tools

Design Price Wholesale China Lithium Cordless Drill Manufacturer In the realm of power tools, the China lithiu...

View More -

Ensuring Safety When Using Electric Buffer Polisher And Electric Chain Saw Machine

Design High Quality Electric Buffer Polisher Chain Saw Machine Exporter When operating power tools like the el...

View More

Industry Knowledge Extension

Unleashing Precision and Power: The Function of Electric Metal Cut-off Chop Saw Machines

In the world of metalworking, precision is paramount. Whether you're crafting a beautiful piece of art from steel, fabricating essential components for machinery, or performing routine maintenance on your vehicle, achieving precise and clean cuts is a fundamental requirement. Enter the electric metal cut-off chop saw machine – a versatile and indispensable tool for metalworkers and enthusiasts alike.

The Basics: What is an Electric Metal Cut-off Chop Saw Machine?

An electric metal cut-off chop saw machine, often referred to simply as a chop saw, is a power tool designed for cutting various types of metal materials with accuracy and efficiency. These machines are engineered to make clean, straight, and precise cuts through metal bars, pipes, tubes, and other metal stock. They are favored for their speed, reliability, and ability to produce burr-free cuts.

The Core Functionality: How Does It Work?

At the heart of an Electric Metal Cut-off Chop Saw Machine is a circular cutting blade specifically designed for metal cutting. This blade is typically made of high-speed steel (HSS) or carbide-tipped materials to withstand the rigors of cutting through tough metals. The blade is mounted on a pivoting arm, which allows it to move up and down.

The cutting process is initiated by the operator, who securely clamps the metal workpiece in place on the saw's base or vice. Once the material is securely positioned, the blade is manually lowered onto the metal. The high-speed rotation of the blade generates a tremendous amount of cutting force, slicing through the metal with ease.

Electric Metal Cut-off Chop Saw Machines are equipped with powerful electric motors that drive the blade's rotation. These motors are engineered for optimal performance, providing the necessary speed and torque to cut through different metals efficiently. The user can often adjust the cutting speed and depth to accommodate various material thicknesses and hardness levels.

Versatility Beyond Compare

Electric metal cut-off chop saw machines are versatile tools that excel in various metalworking applications. Here's a glimpse of their versatility:

Metal Fabrication: In metal fabrication shops, Electric Metal Cut-off Chop Saw Machines are used to cut metal stock into precise lengths and shapes for further processing. Whether it's cutting steel beams, aluminum profiles, or stainless steel tubes, chop saws deliver accurate results.

Construction: On construction sites, Electric Metal Cut-off Chop Saw machines are essential for cutting metal pipes, angles, and channels used in structural framing, plumbing, and electrical installations.

Automotive Work: Automotive enthusiasts and professionals use Electric Metal Cut-off Chop Saw Machine to cut and shape metal components for vehicle modifications and repairs. From exhaust pipes to suspension components, chop saws ensure precise cuts for a perfect fit.

Artistic Creations: Metal artists and sculptors rely on Electric Metal Cut-off Chop Saw Machine to transform raw metal materials into intricate sculptures and artworks. The precision of these machines allows for intricate detailing and fine craftsmanship.

Home Improvement: For DIY enthusiasts and homeowners, chop saws come in handy for a wide range of tasks, including cutting metal shelves, brackets, and hardware for home improvement projects.

Benefits That Set Chop Saws Apart

Electric metal cut-off chop saw machines offer a multitude of benefits that make them indispensable tools in metalworking:

1. Speed and Efficiency: Chop saws are renowned for their speed, allowing operators to make quick and efficient cuts. This is particularly valuable in production and industrial settings where time is of the essence.

2. Precision: The accuracy of the Electric Metal Cut-off Chop Saw Machine is unmatched. They produce clean, square cuts that require minimal finishing or deburring, saving time and effort.

3. Versatility: From cutting thin sheet metal to thick steel beams, chop saws can handle a wide range of metal materials and thicknesses.

4. Durability: The robust construction of chop saws, including their heavy-duty frames and powerful motors, ensures their longevity and reliability.

5. Safety Features: Modern chop saws are equipped with safety features such as blade guards, anti-kickback mechanisms, and ergonomic handles to enhance operator safety.

6. Burr-Free Cuts: Electric Metal Cut-off Chop Saw Machine produces cuts with minimal burring, reducing the need for additional finishing work.

7. Portability: While often used in fixed locations, some chop saw models are designed for portability, allowing users to transport them to job sites easily.

English

English Español

Español